Assembling ETRI axial fans in series or in parallel

Adapt airflow to ventilation requirements

High-performance ETRI axial fans can be made even more efficient thanks to a specific assembly adapted to the ventilation requirement, the pressure imposed and the space available in your installation.

The airflow levels required vary according to the surface area to be ventilated or the power of the appliances to be cooled. Static pressure levels vary considerably from one application to another: the structure of an installation means that the fan will have to overcome higher or lower pressure to perform its role correctly. One of the solutions offered by ETRI is to assemble axial fans in series or parallel.

- A simple axial-flow fan consists of a motor, an impeller and a rectifying housing.

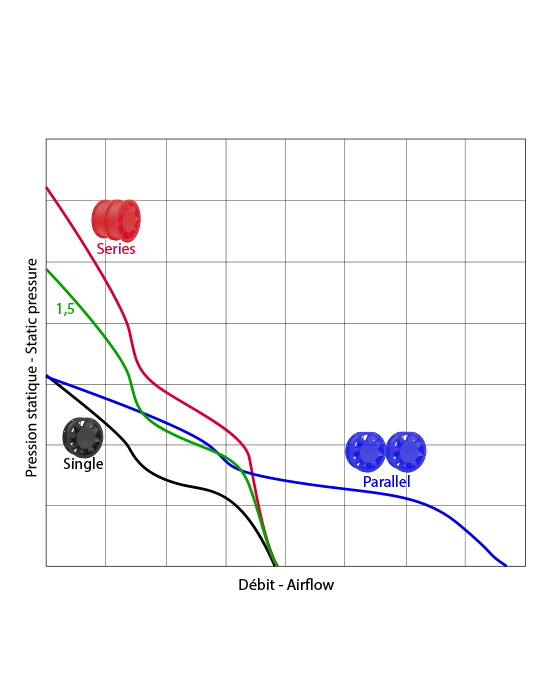

- ETRI fans can be assembled in series, i.e. with an additional rectifying housing at the air inlet or outlet. This assembly consists of a single motor, two impellers and two rectifying housings. In this case, there is only one air inlet and one air outlet. This enables the fan to deliver almost twice the static pressure of a simple axial fan, while providing the same airflow.

- In a parallel assembly, two ETRI axial fans are assembled side by side. The assembly consists of two motors, two impellers and two rectifying housings. In this case, there are two air inlets and two air outlets. This type of assembly is suitable for applications where there is no high static pressure, but a high level of air flow is required. Parallel assembly delivers almost twice the airflow than a single axial fan at the same pressure.

- To go even further and meet the specific needs of an application, we can even assemble two propellers with a single rectifying housing (what we call a "1.5" assembly). In some cases, the performance of a single axial is not sufficient, and the performance of a double axial in series is too high. That's why we've developed a ventilation solution with two impellers but a single rectifying housing.

The aeraulic curve below shows the differences in air flow and static pressure between the various assemblies.

The table below shows the proportional differences in airflow, static pressure, power and sound levels between the different assemblies:

| Airflow | Pressure | Power | Acoustic | |

| m³/h | Pa | W | dB(A) | |

| Simple | 1 | 1 | 1 | 1 |

| Series | 1 | ~ x2 | ~ x1,6 | ~ +5 |

| Paralell | ~ x2 | 1 | ~ x2 | ~ +3 |

| 1,5 | 1 | ~ x1,6 | ~ x1,4 | ~ +5 |

As a complement to these high-performance ventilation assemblies, we can also add mounting flanges specifically adapted to our customers' interfaces.

Our technical sales and engineering teams are at your disposal right from the start of your project to develop the ventilation solution that's right for your application.